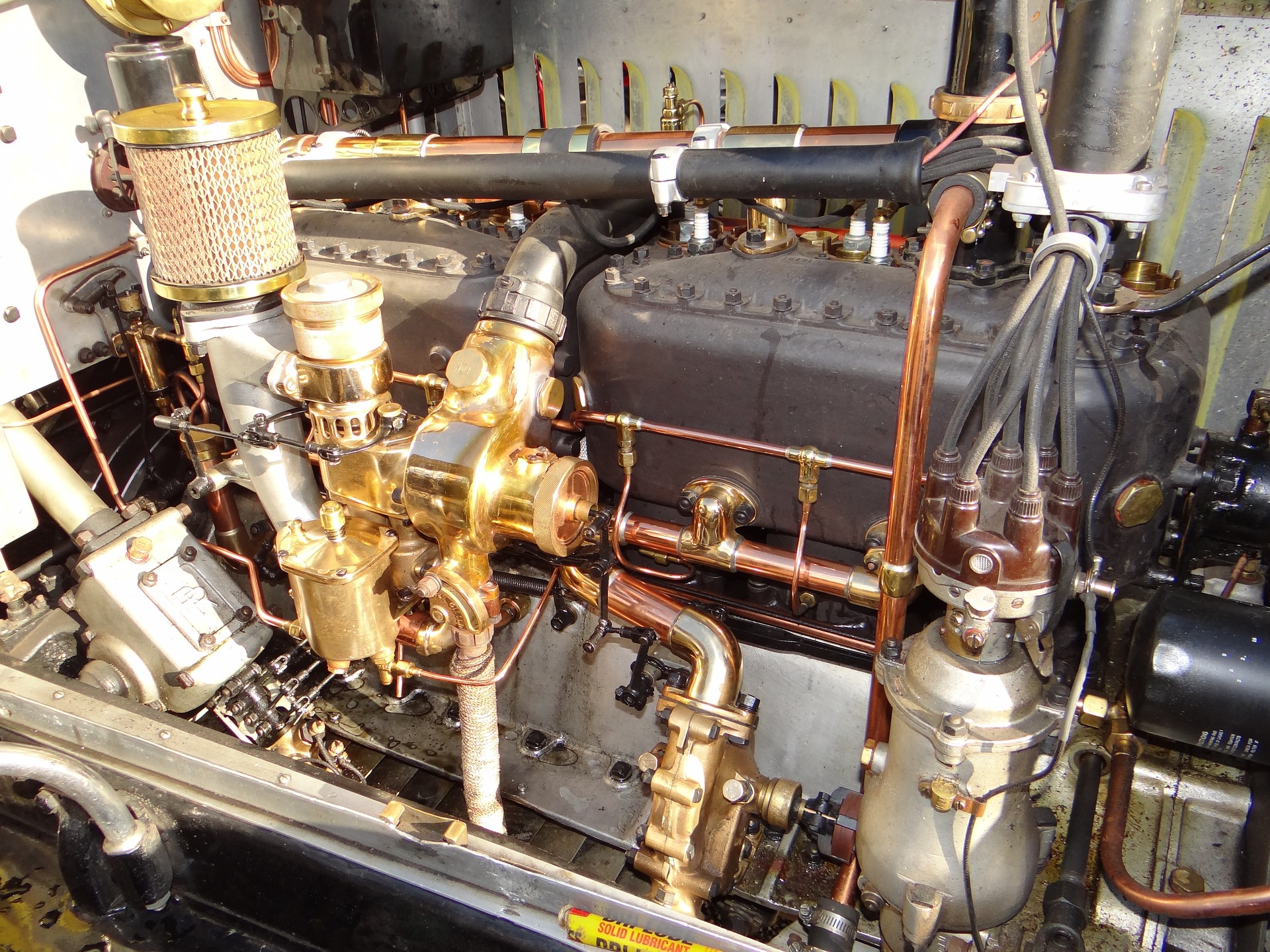

Have you ever wondered why your car’s engine needs oil? Apart from lubricating engine components, the oil has several important functions, like transferring heat away from the engine and preventing corrosion of engine parts. However, oil can only function effectively if its condition is monitored to ensure that it is clean, at the correct temperature, and level. This is where an oil condition monitoring system comes in.

An oil condition monitoring system is a set of sensors and diagnostic tools that checks the condition of the oil, allowing you to identify problems before they escalate. It prevents equipment failure or unnecessary downtime, reducing maintenance costs and, ultimately, increasing productivity.

With the right oil condition monitoring system, you can reduce unscheduled maintenance by as much as 56 percent, according to a report by the Aberdeen Group. The system identifies potential failures or poor performance, enabling you to make data-driven decisions that will prevent breakdowns or costly repairs.

In addition to reducing maintenance costs, using an oil condition monitoring system can help you optimize your equipment’s performance. By ensuring that the oil is always in peak condition, the engine will run more efficiently, increasing productivity and reducing fuel consumption.

An oil condition monitoring system is essential for any business that relies on engines or other lubricated equipment to run their operation. By monitoring the oil’s condition, identifying potential problems, and optimizing performance, you can keep your equipment running smoothly and save money in the long run.